Tecparts of Brazil started its activities in 2003, manufacturing autoparts, especially machined castings.

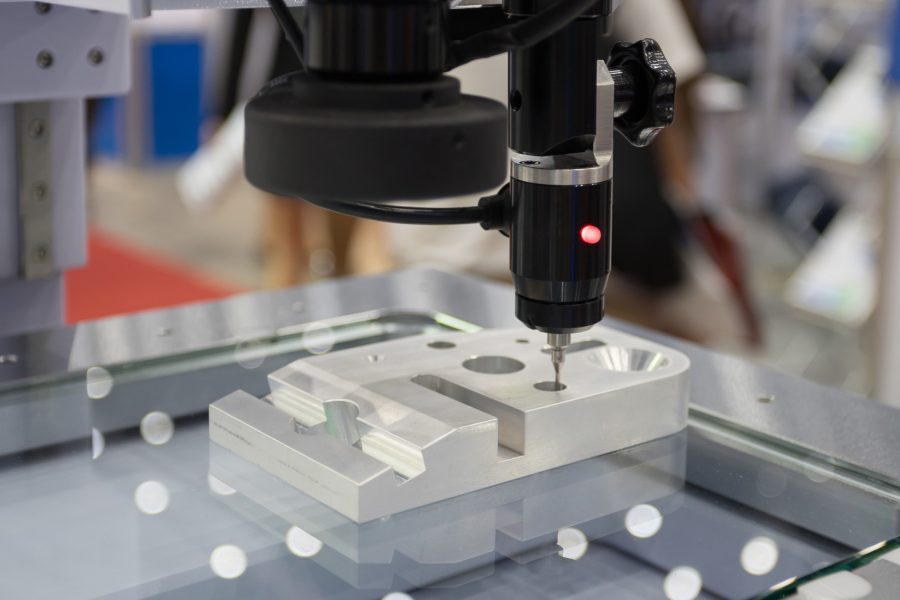

Our facilities in Piracicaba/SP Brazil are equipped with modern CNC machines.

We count on skilled team to support our production and supply to our customers the best products for local and international markets.

Tecparts’ Mission is organized teamwork, always seeking customer satisfaction. Each person is an important and valuable member of this team, who strives to perform with excellence, ensuring a reliable, economical and quality product.

Tecparts’ Vision is to remain one of the main companies in the sectors in which it operates, always seeking technological innovation, efficiency and customer satisfaction. We aim to be a reference in quality and delivery precision, raising a partnership relationship with our customers.

Our main values are: Focus on customer, Protecting the environment, Respect for people.

Making the best OEM components on the market, protecting the environment and being remembered by customers for their quality and reliability.

The Tecparts Code of Conduct and Ethics reflects the principles that guide our actions and relationships. We are committed to transparency, respect, and integrity in all interactions with employees, clients, suppliers, and society. We value excellence, social responsibility, and respect for diversity, rejecting all forms of discrimination, harassment, child labor, or forced labor.

Our guidelines include sustainable practices, strict compliance with the law, and a firm stance against corruption, promoting equity and inclusion. We prioritize safety, health, and quality of life, ensuring an ethical and safe work environment. We engage with suppliers and clients fairly and reliably, preserving confidentiality and impartiality.

We believe in the importance of transparent communication and the responsible use of company resources. We do not tolerate abuse of power, unethical practices, or actions that compromise the integrity of the company. Adherence to the Code is essential for maintaining our mission, vision, and values in alignment with global best practices.

All stakeholders are responsible for promoting and adhering to these guidelines, strengthening our identity as an ethical and responsible organization.

More than 800 machined, forged and casting parts and components for tractors, automobiles, machines and wind power generation. Complete portfolio of products such as covers, housings, shafts, switching shafts, levers, chassis and transmission boxes components, in cast iron and cast steel, as well as pins, bushings, joints, special screws, made form steel bars and tubes, treated and painted inside the company.

Respect the environment is a priority at Tecparts. The company complies with all environmental regulations and has water and oil reuse processes, reducing impacts on the environment to a minimum. Tecparts uses energy from 100% renewable sources.

Quality assurance in all Tecparts product lines, with ISO 9001 │ ISO 14001 │ IATF 16949 certifications.

Quality policy:

TECPARTS is committed to developing Machining Processes and manufacturing quality products, meeting its requirements and those of interested parties, aiming at continuous improvement of the Quality Management System, customer satisfaction and business profitability.

Metallographic laboratory: evaluation of products in macro and micrographs, material structure analysis, hardness evaluation, ultrasound tests, thickness evaluation for painting layers and hardening depth, contamination tests.

Our warranty and Support area is focused on providing our customers with the best solutions.